Menene PLA?

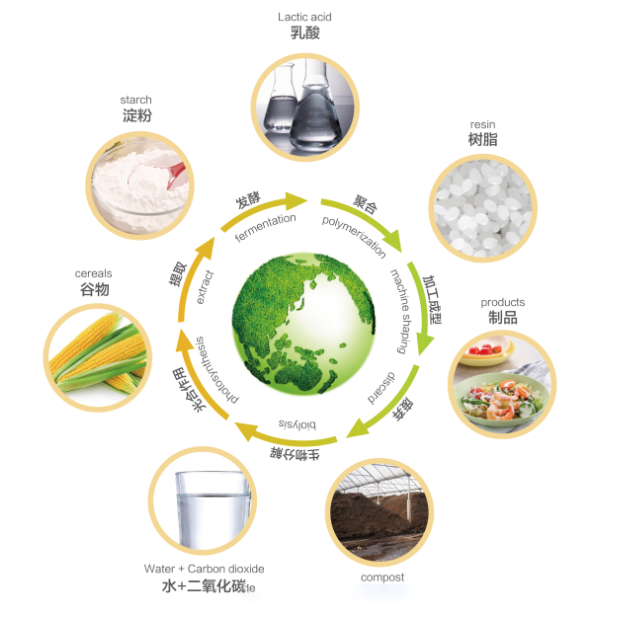

Polylactic acid, wanda kuma aka sani da PLA (Polylactic Acid), monomer ne na thermoplastic wanda aka samo daga tushen kwayoyin halitta masu sabuntawa kamar sitaci na masara ko rake ko ɓangaren litattafan gwoza.

Duk da cewa ya yi daidai da robobin da suka gabata, dukiyoyinsa sun zama albarkatun da za a iya sabunta su, wanda hakan ya sa ya zama madadin dabi'ar mai.

PLA har yanzu tsaka tsakin carbon ne, wanda ake iya ci, da kuma biodegradable, wanda ke nufin zai iya rugujewa gaba ɗaya a cikin wuraren da suka dace maimakon kutsawa cikin microplastics masu cutarwa.

Saboda iyawar sa na rubewa, ana amfani da shi azaman marufi don buhunan robobi masu lalacewa, bambaro, kofuna, faranti, da kayan tebur.

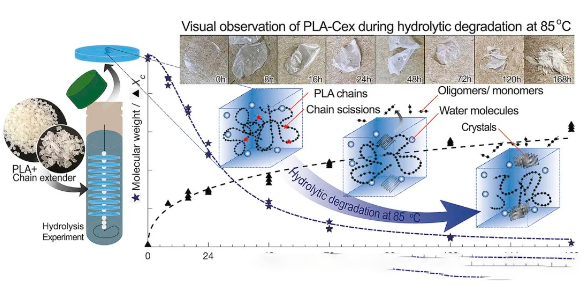

Tsarin lalata na PLA

PLA yana fuskantar rashin lalacewar halittu ta hanyoyi uku:

Hydrolysis: Ƙungiyoyin ester a cikin babban sarkar sun karye, yana haifar da raguwar nauyin kwayoyin halitta.

Bazuwar thermal: wani abu mai rikitarwa wanda ke haifar da samuwar mahadi daban-daban, irin su ƙwayoyin cuta masu sauƙi, masu layi da cyclic oligomers tare da ma'auni daban-daban, da lactide.

Photodegradation: Ultraviolet radiation na iya haifar da lalacewa. Wannan shi ne babban abin da ke fallasa polylactic acid zuwa hasken rana a cikin filastik, kwantena marufi, da aikace-aikacen fim.

Halin hydrolysis shine:

-COO- + H 2 O → -COOH + -OH

Matsakaicin raguwa yana jinkiri sosai a yanayin zafi. Wani bincike na 2017 ya gano cewa PLA ba ta sami asarar inganci ba a cikin shekara guda a cikin ruwan teku a 25 ° C (77 ° F), amma binciken bai auna bazuwar ko sha ruwa na sarƙoƙi na polymer ba.

Menene yankunan aikace-aikacen PLA?

1. Kayayyakin masu amfani

Ana amfani da PLA a cikin kayan masarufi daban-daban, kamar kayan tebur da za'a iya zubar da su, manyan kantunan sayayya, akwatunan kayan dafa abinci, da kwamfyutoci da na'urorin hannu.

2. Noma

Ana amfani da PLA a cikin nau'in fiber don layin kamun fiber guda ɗaya da tarukan ciyayi da sarrafa ciyawa. Ana amfani da shi don jakan yashi, tukwanen fure, madaurin ɗaure, da igiyoyi.

3. Magani

Ana iya lalata PLA zuwa lactic acid mara lahani, yana mai da shi dacewa don amfani da shi azaman kayan aikin likita a cikin nau'ikan anka, sukurori, faranti, fil, sanduna, da raga.

Hudu mafi yawan gama-gari yanayi mai yuwuwar gogewa

1. Sake yin amfani da su:

Yana iya zama sake amfani da sinadarai ko sake yin amfani da injina. A Belgium, Galaxy ta ƙaddamar da masana'antar gwaji ta farko don sake amfani da sinadarai na PLA (Loopla). Ba kamar sake yin amfani da injina ba, sharar gida na iya ƙunsar ƙazanta daban-daban. Ana iya dawo da acid polylactic ta hanyar sinadarai azaman monomers ta hanyar polymerization na thermal ko hydrolysis. Bayan tsarkakewa, ana iya amfani da monomers don kera raw PLA ba tare da rasa ainihin kayansu ba.

2. Taki:

Ana iya lalata PLA a ƙarƙashin yanayin takin masana'antu, ta farko ta hanyar hydrolysis na sinadarai, sannan ta hanyar narkewar ƙwayoyin cuta, kuma a ƙarshe ya lalace. A karkashin yanayin takin masana'antu (58 ° C (136 ° F)), PLA na iya jujjuya (kimanin rabin) cikin ruwa da carbon dioxide a cikin kwanaki 60, tare da ragowar ɓangaren bazuwar sannu a hankali bayan haka, dangane da crystallinity na kayan. A cikin yanayin da ba tare da larura ba, bazuwar zai kasance a hankali, kama da robobin da ba na halitta ba, waɗanda ba za su ruɓe gaba ɗaya ba na ɗaruruwan ko dubban shekaru.

3. Konawa:

Ana iya ƙone PLA ba tare da samar da chlorine mai ɗauke da sinadarai ko ƙarfe masu nauyi ba, saboda kawai ya ƙunshi carbon, oxygen, da hydrogen atom. Ƙonawar PLA za ta samar da 19.5 MJ/kg (8368 btu/lb) na makamashi ba tare da barin wani rago ba. Wannan sakamakon, tare da wasu binciken, yana nuna cewa ƙonewa hanya ce mai dacewa da muhalli don magance polylactic acid sharar gida.

4. Gurasa:

Ko da yake PLA na iya shiga wuraren ajiyar ƙasa, shine mafi ƙarancin zaɓi na abokantaka na muhalli saboda kayan suna raguwa sannu a hankali a yanayin yanayin yanayi, yawanci a hankali kamar sauran robobi marasa lalacewa.

Lokacin aikawa: Nuwamba-20-2024